Context

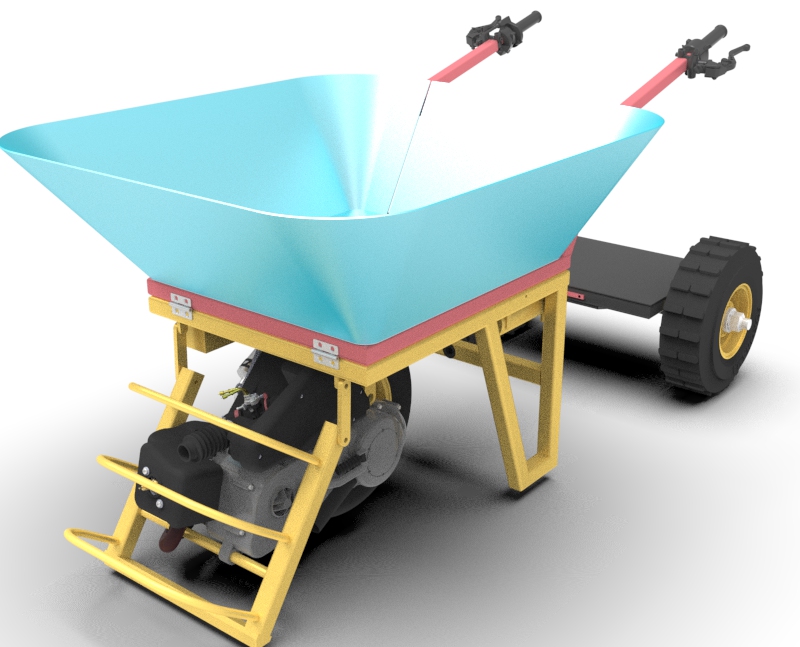

In Cameroon, wheelbarrows are essential for construction, farming, and market activities, but

traditional models require heavy manual effort.

Our goal was to design a motorised wheelbarrow that is easy to use, comfortable, and

adaptable to users of different heights (1.5m to 1.9m), while working with limited resources

and without relying on 3D modeling or simulations.

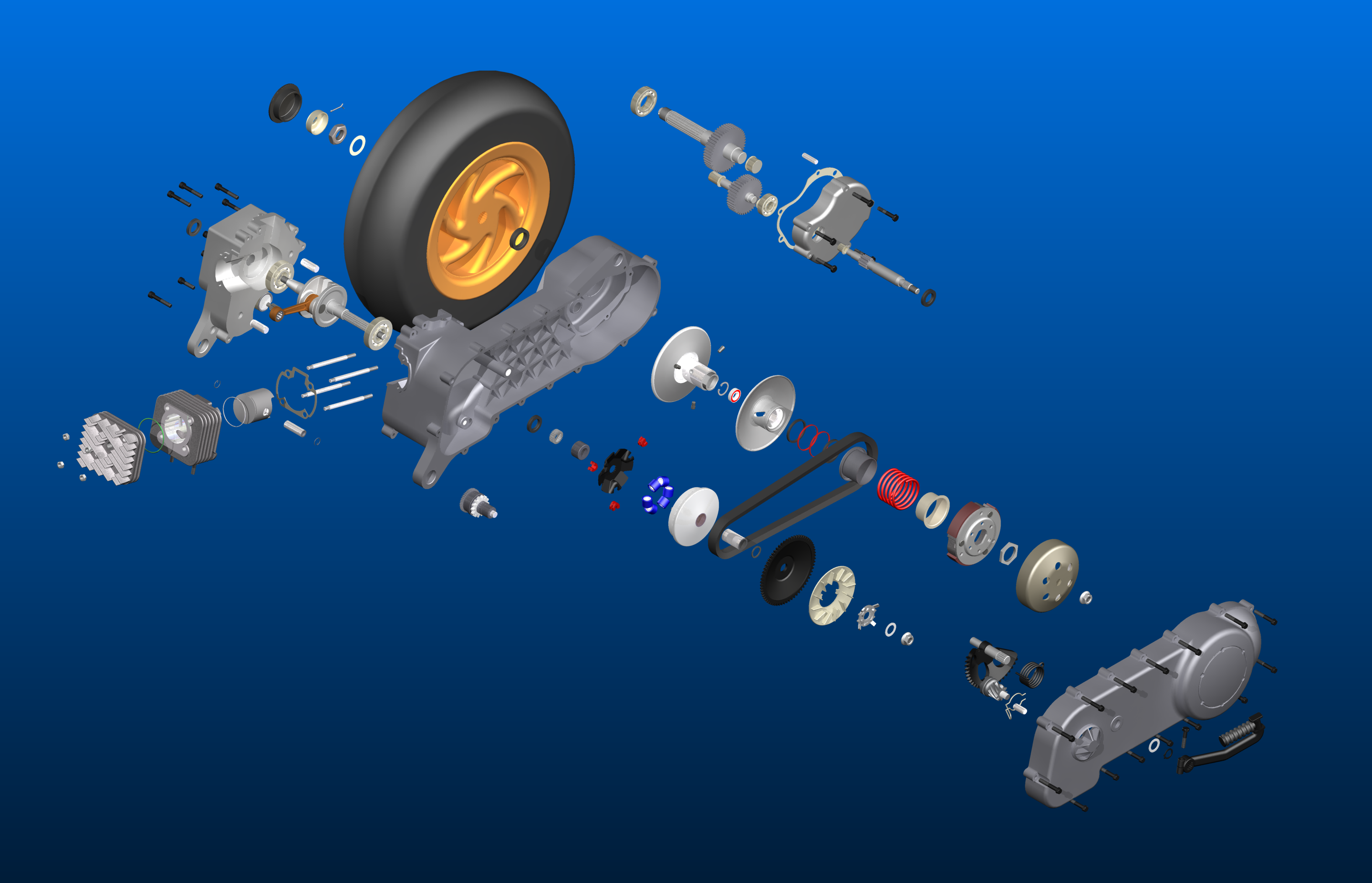

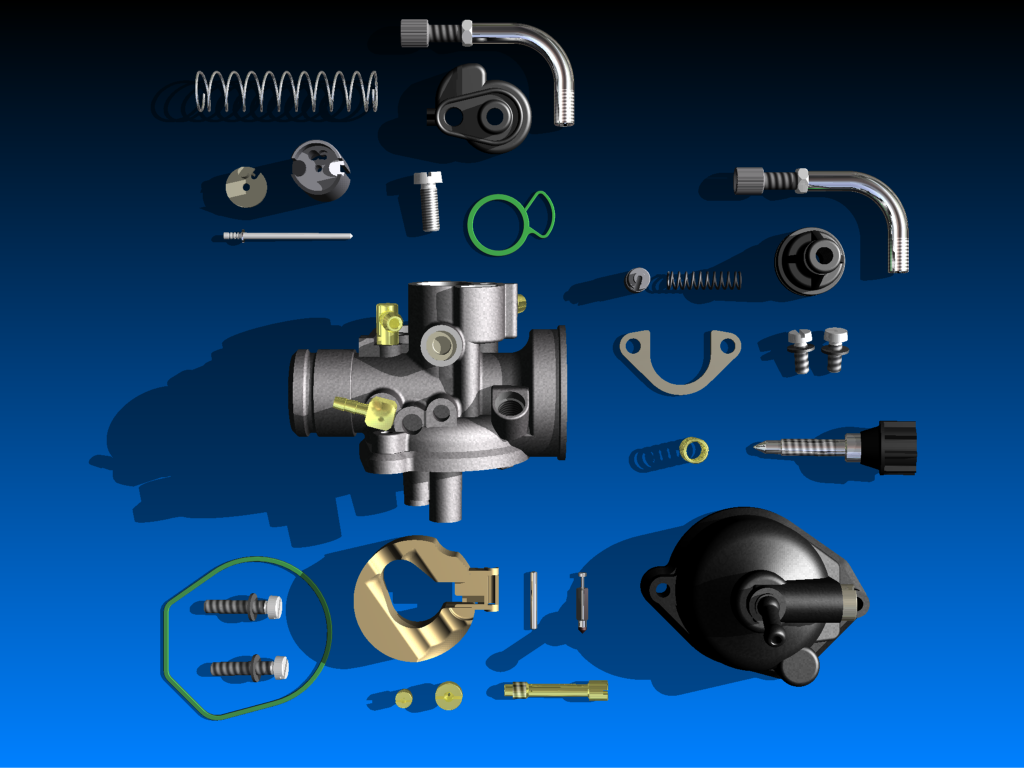

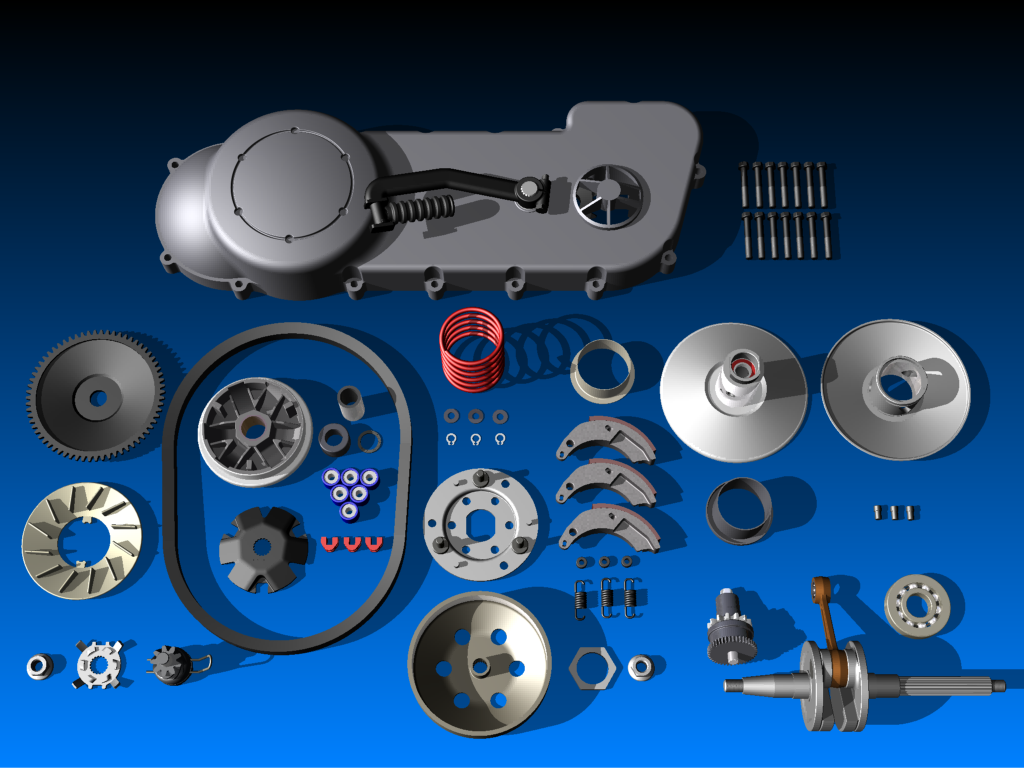

We chose a reconditioned e-scooter motor with a pre-mounted wheel (~35-40cm), which was

perfect for ergonomics and easier integration. It took three weeks to source a reliable

motor within budget.

Content

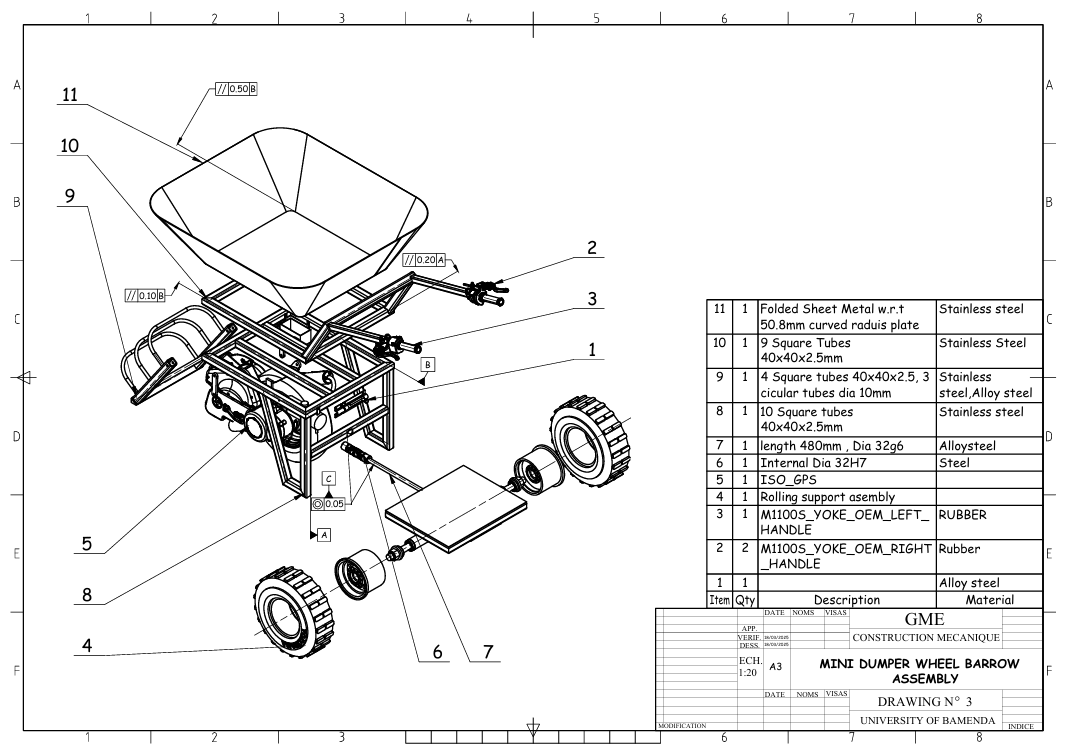

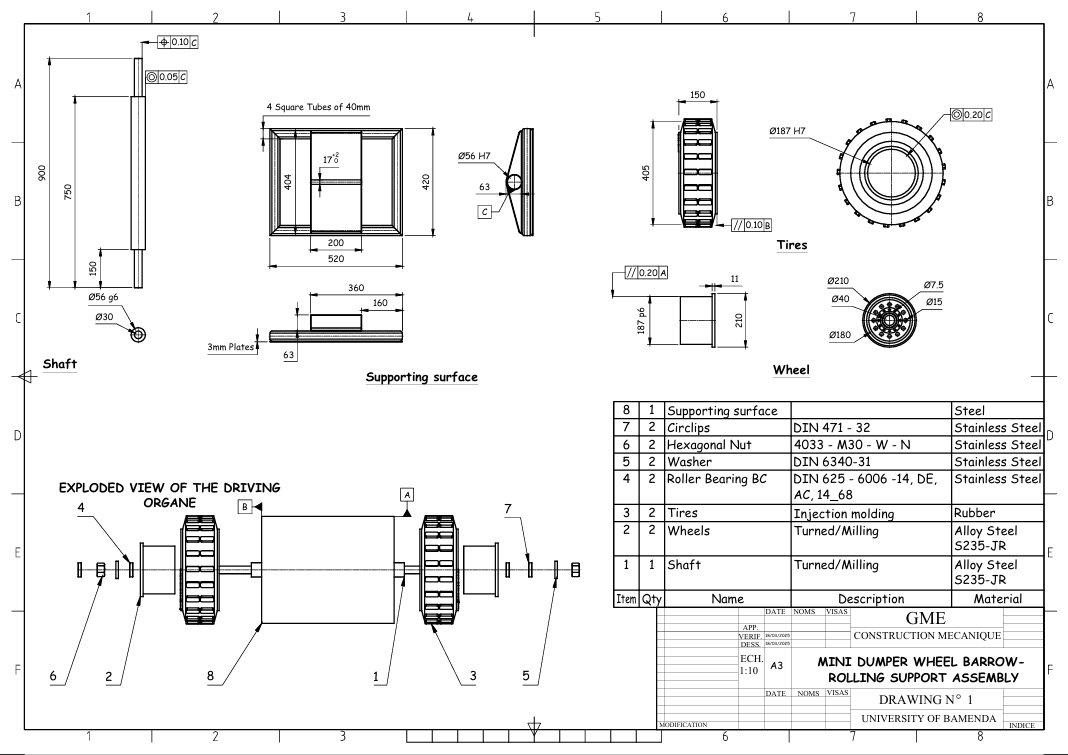

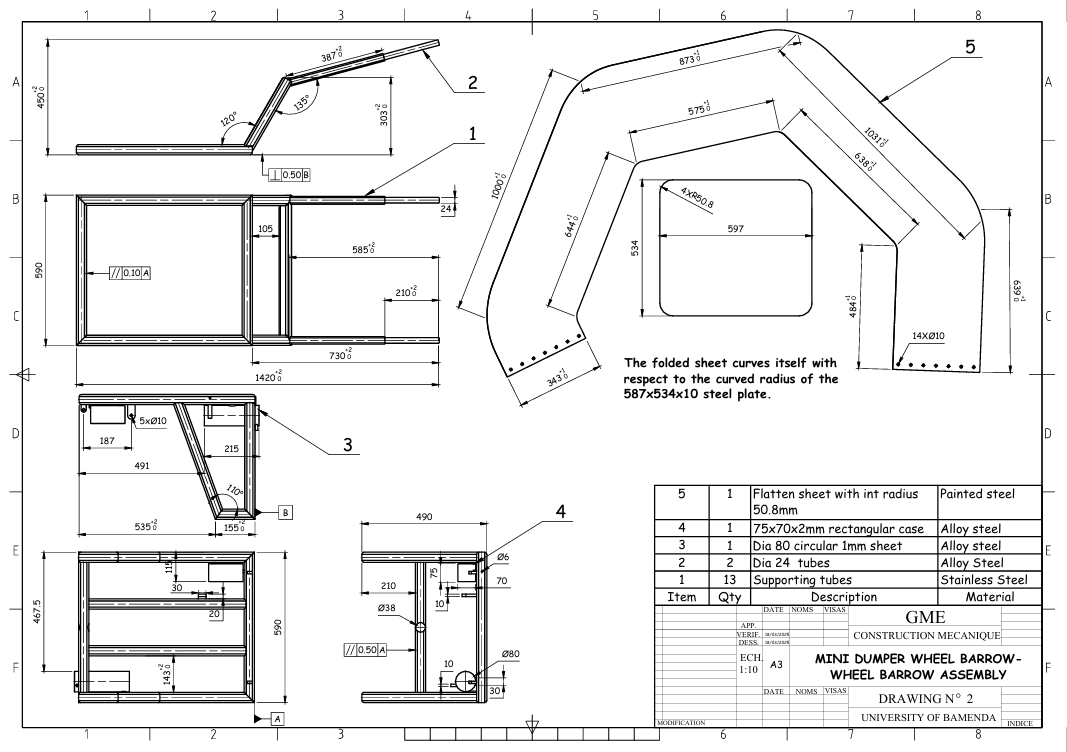

This project was purely hands-on engineering: welding, cutting, and assembling the frame

without CAD or simulations—just experience, measurement, and iterative thinking.

Key design considerations included: battery and oil tank placement for accessibility; wheel

and handle configuration for users from 1.5m to 1.9m; and motor integration with handles

positioned for intuitive operation.

Collaboration was essential. When Badou suggested an adjustable "elevator"

system for shorter users, budget constraints required a creative solution: larger wheels

that raised the user slightly, balancing comfort and cost.

Conclusions

The motorised wheelbarrow was successfully completed in three weeks, supporting male users

(1.75-1.90m) and female users (1.50-1.90m) comfortably.

This hands-on approach proved faster than creating 3D models and simulations, which could

have taken 4-6 weeks longer given our resources.

Key lessons learned: not all projects need CAD; collaboration ensures functional, inclusive

designs; ergonomics are essential for usability; and resourcefulness drives innovation under

budget constraints.