Compressor test bench optimization

At CAMRAIL, I worked on the optimization and reconfiguration of mechanical

and pneumatic systems on intercity locomotives, focusing on aging models such as the

BB1100, CC2200, CC3300, and CC2200, within the context of rolling stock and spare parts shortages.

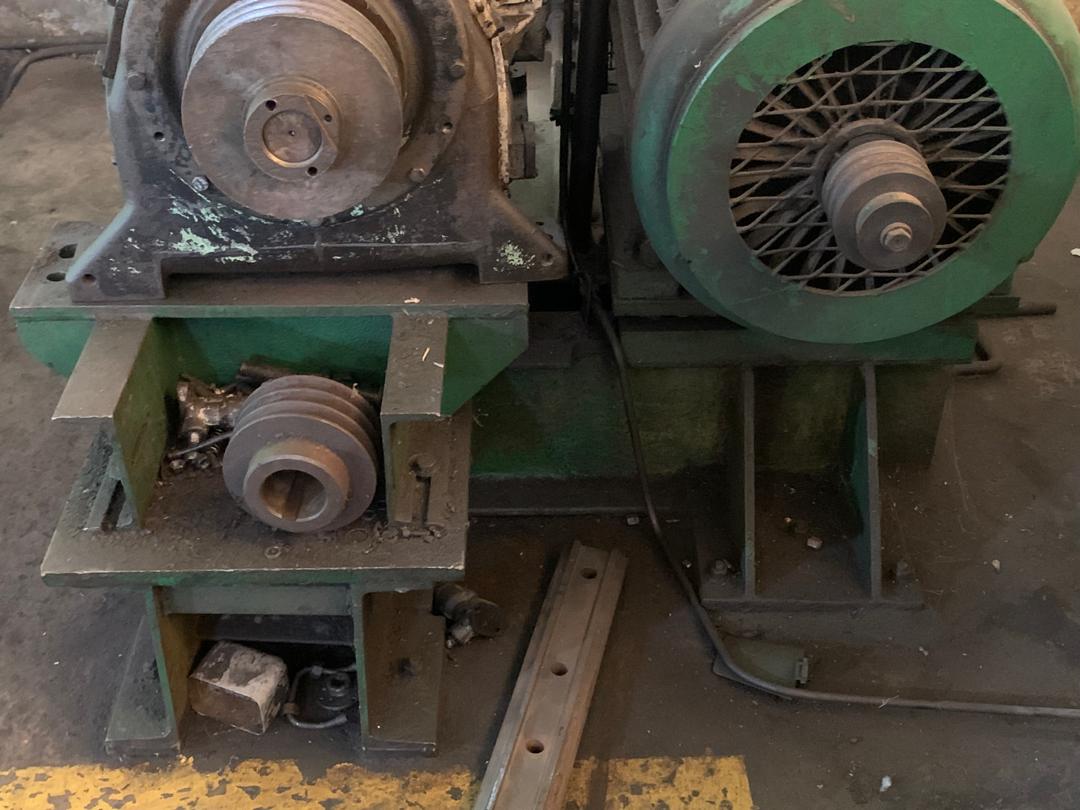

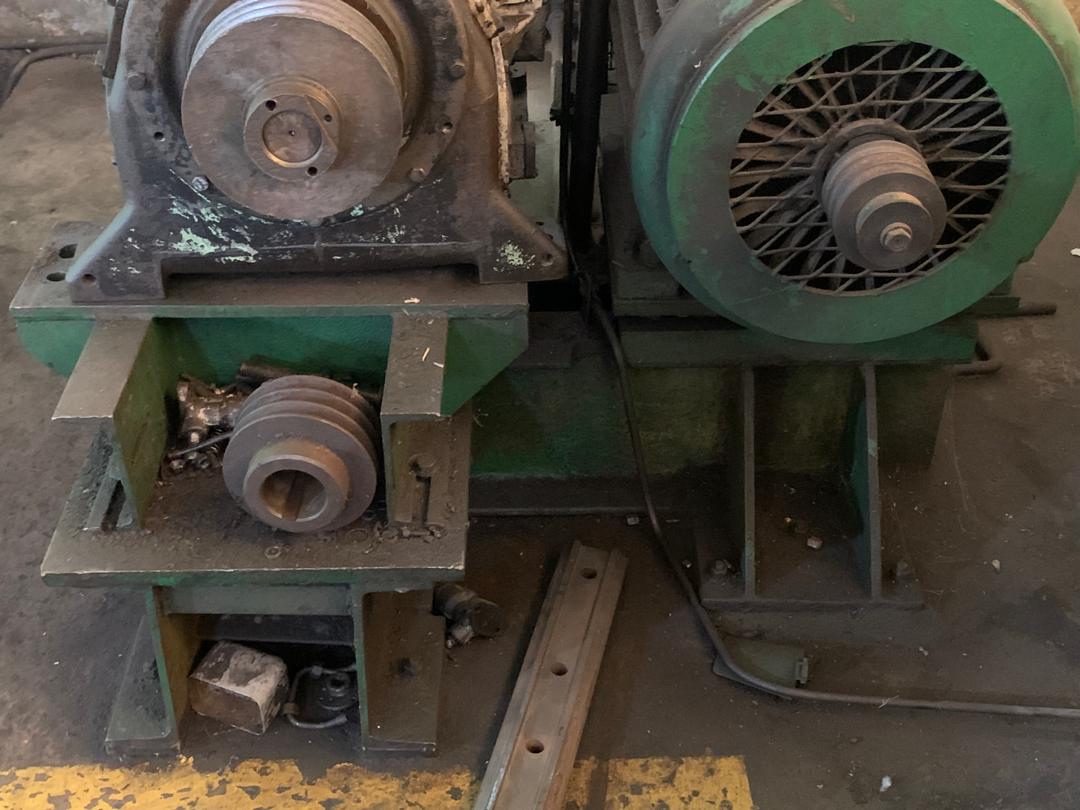

During one critical phase, while preparing locomotives for operational validation, we uncovered

subtle incompatibilities in the locomotive compressor test bench—a crucial tool for

preventive and corrective maintenance. To fully understand the problem and how it was addressed, it

is necessary to first understand what the compressor does and how the test bench interfaces with it.

The locomotive compressor ensures air compression and oil circulation, which are essential for

pneumatic systems like braking, control, and auxiliary operations. After significant mileage,

compressors require inspection, oil changes, and cleaning. Testing on the bench is therefore

critical to verify proper functioning, detect leaks, and ensure reliability before reinstallation in

the locomotive. The existing bench, however, was limited to testing only BB1100 and CC2200

compressors. Other models, such as CC3300, CC3300 AC, and CC2200, required fragmented and

inefficient testing in separate locations, including water tests in the wash area and hydraulic

tests in the garage, which introduced time loss, movement inefficiencies, traceability issues, and

higher risk of errors.

My role was to define and implement a new testing methodology to transform the

bench into a versatile, modular, and universal system capable of performing pressurized air, water,

and oil tests across multiple compressor types. This involved:

- 3D Modeling and Design: I completed a full 3D model of the bench, including the

main frame, mounting interfaces, and functional testing zones. The design accommodated

compressors of widely varying sizes and weights, from compact BB1100 units to larger CC3300

compressors.

- Low-Cost Modular Frame: The frame was designed for compatibility with multiple

compressors, ease of assembly and disassembly, reduced manufacturing costs, and sufficient

mechanical rigidity to limit vibrations during testing.

- Functional Analysis and Dynamic Constraints: I analyzed vibration

characteristics, forces from air and fluid jets, and potential interactions between compressors

and the bench structure to prevent instability or mechanical failure during testing.

Beyond the test bench, I also addressed recurrent radiator overheating in

locomotives. This issue arose due to aging fleet components, unavailability of original parts, and

the integration of locally designed alternatives that disrupted airflow. My responsibilities

included analyzing ventilation impacts, proposing pneumatic system modifications, integrating

additional radiator ventilation devices, and ensuring the changes did not interfere with other

mechanical or pneumatic systems.

Brake supports design

During my time at CAMRAIL, I served as a technical contributor on the brake support design and

adaptation project for BB1100 and CC3300 locomotives, where original components were no longer

available due to supply chain constraints and obsolescence. Working in small technical teams, I

confronted a technically challenging task that required us to build the metaphorical fighter jet

while flying it. At CAMRAIL, I was tasked with designing and validating brake supports essential for

safe braking operations under the demanding conditions of heavy freight transport. During my

preliminary analysis, I uncovered an insidious incompatibility between the aging mechanical

components and the performance requirements for modern operations. In these pneumatic braking

systems, compressed air at 3.8 bars actuates brake cylinders that apply force through a lever

mechanism to brake shoes pressing against the wheel's rolling surface. The brake support structure

serves as the critical load path between the motorized actuator system and the locomotive's bogie

frame. During my investigation, I found that our existing support showed three fundamental failure

modes: excessive mechanical play caused by wear of axles and pivots reducing braking precision,

fatigue of suspension springs from continuous vibrations leading to loss of rigidity, and corrosion

of components from prolonged exposure to weather weakening structural integrity. I documented how

these degradation mechanisms manifested as diminished braking effectiveness with longer stopping

distances, increased risk of mechanical failure during critical braking events, and potentially

catastrophic component breakdowns under load.

Our experienced mechanical engineers in the workshop jumped to conclusions about what they thought

was wrong, and rightfully so—they had solid understanding of how the system worked, having

maintained these locomotives for years. I called the room to order, grabbed an empty cardboard box

out of the workshop (for some reason, this is a theme with me), and started with a single question

to the group: what are we actually observing? We were seeing premature wear and excessive deflection

in the support structure, and my visual inspection revealed corrosion at weld joints while my

dimensional measurements confirmed play in the pivot connections exceeded specification limits by

300%. I called attention to the distinction between observing the symptoms and understanding the

root causes, and I pushed through the rest of the exercise in what I call "low-gear problem-solving"

while gathering insights from the engineers who were far more experienced with these systems than I.

Soon I had a sprawling fault tree on the large, flattened cardboard box, and I circled what we

agreed were the most probable failure mechanisms and brainstormed how I could "lay a trap" for the

problem through systematic analysis.

After splitting the analysis work between team members, I got to work on the solution using

SOLIDWORKS for 3D modeling and ANSYS for finite element analysis to design an optimized brake

support that addressed all identified failure modes. I added gusset reinforcements at critical load

paths to stiffen the structure and reduce deflection, with the support connecting the pneumatic

motor assembly to the bogie frame to dissipate braking forces without transmitting undesirable

stress concentrations to the bogie structure. I specified S235JR structural steel for the main

support structure, selected for its adequate yield strength, good weldability for fabrication,

resistance to fatigue under cyclic loading, and cost-effectiveness for rail applications. I refined

the support geometry through iterative analysis to maximize stiffness while minimizing weight,

distribute loads evenly across connection points, eliminate stress concentrations at weld joints,

and provide adequate clearance for maintenance access. My comprehensive structural analysis

validated the design showing adequate safety margins and predicted service life exceeding typical

locomotive overhaul intervals.

The manufacturing process I developed combined precision cutting of steel plate stock,

fixture-assisted alignment for consistent weld joint geometry, MIG welding using qualified

procedures, post-weld grinding and surface preparation, and protective coating for corrosion

resistance. I designed the assembly to follow a systematic protocol with pressure testing, static

load testing to 150% of design braking force, and dynamic testing under simulated braking cycles.

With the optimized brake support I designed and installed, we achieved significant reduction in

maintenance frequency due to reduced wear, improved braking response with tighter mechanical

tolerances, extended component life through superior corrosion resistance, and enhanced safety with

higher structural safety factors. Throughout this project, I applied methodical engineering analysis

using SOLIDWORKS and ANSYS for mechanical design and collaborated closely with multidisciplinary

teams including maintenance personnel, fabrication specialists, and operations staff. By taking a

systematic, evidence-based approach—verifying observations before jumping to conclusions—I delivered

a robust, cost-effective solution that improved locomotive reliability, operational safety, and

maintenance efficiency under real-world industrial constraints. The key to my success was

not just

the technical tools, but the disciplined problem-solving methodology: observe carefully, analyze

systematically, validate thoroughly, and always respect the expertise of those who work with the

equipment every day.