Context

I initiated the Pedal Power Mobile Phone Charger project to solve a problem I witnessed daily

at the University of Douala—frequent power outages left students unable to charge their

phones, disrupting research and communication. As project leader, I assembled a team of

three engineering students at HTTTC to design and build a human-powered charging solution in

just three weeks for the Science and Engineering Festival.

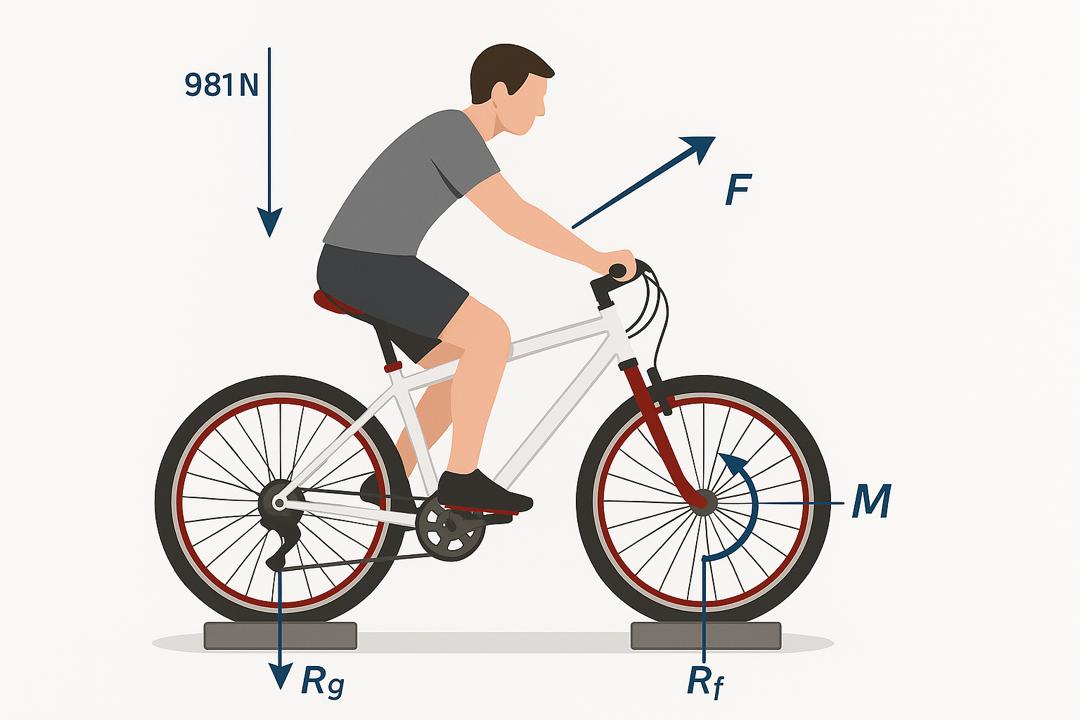

We faced tight constraints: limited budget, no experience with weldment design or FEA, and

the need to accommodate users from 5th to 95th percentile while keeping the device portable.

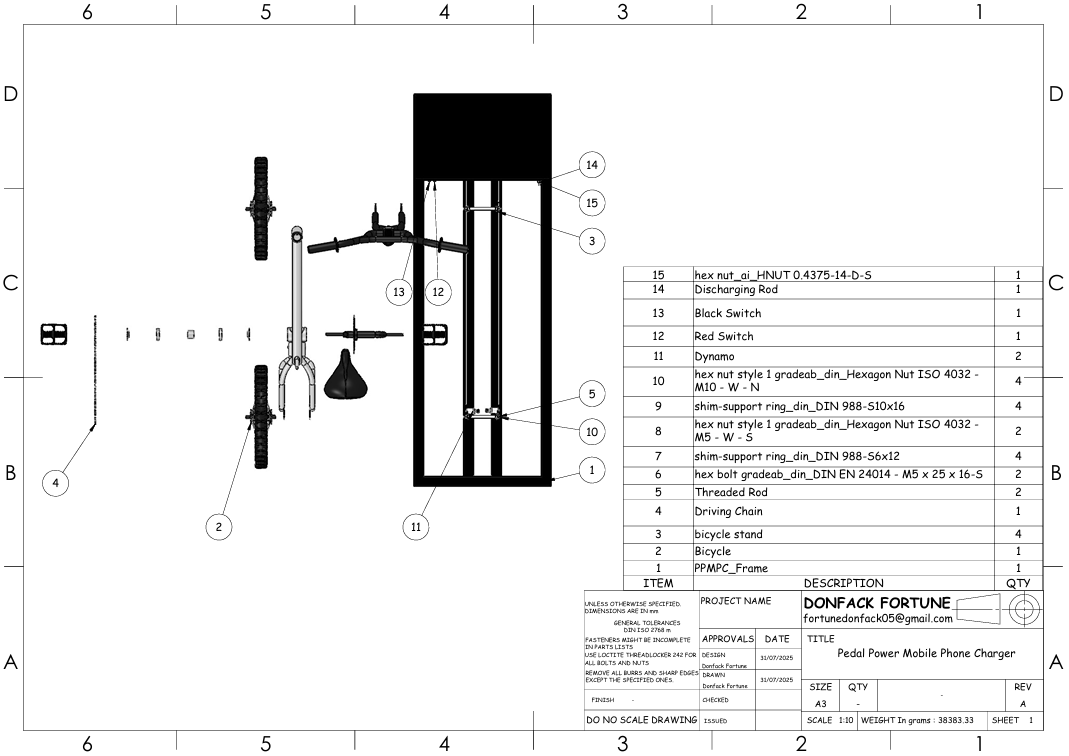

We adopted Design for Manufacturing principles and the

Empathize-Define-Ideate-Prototype-Test framework to guide our rapid development process.

Content

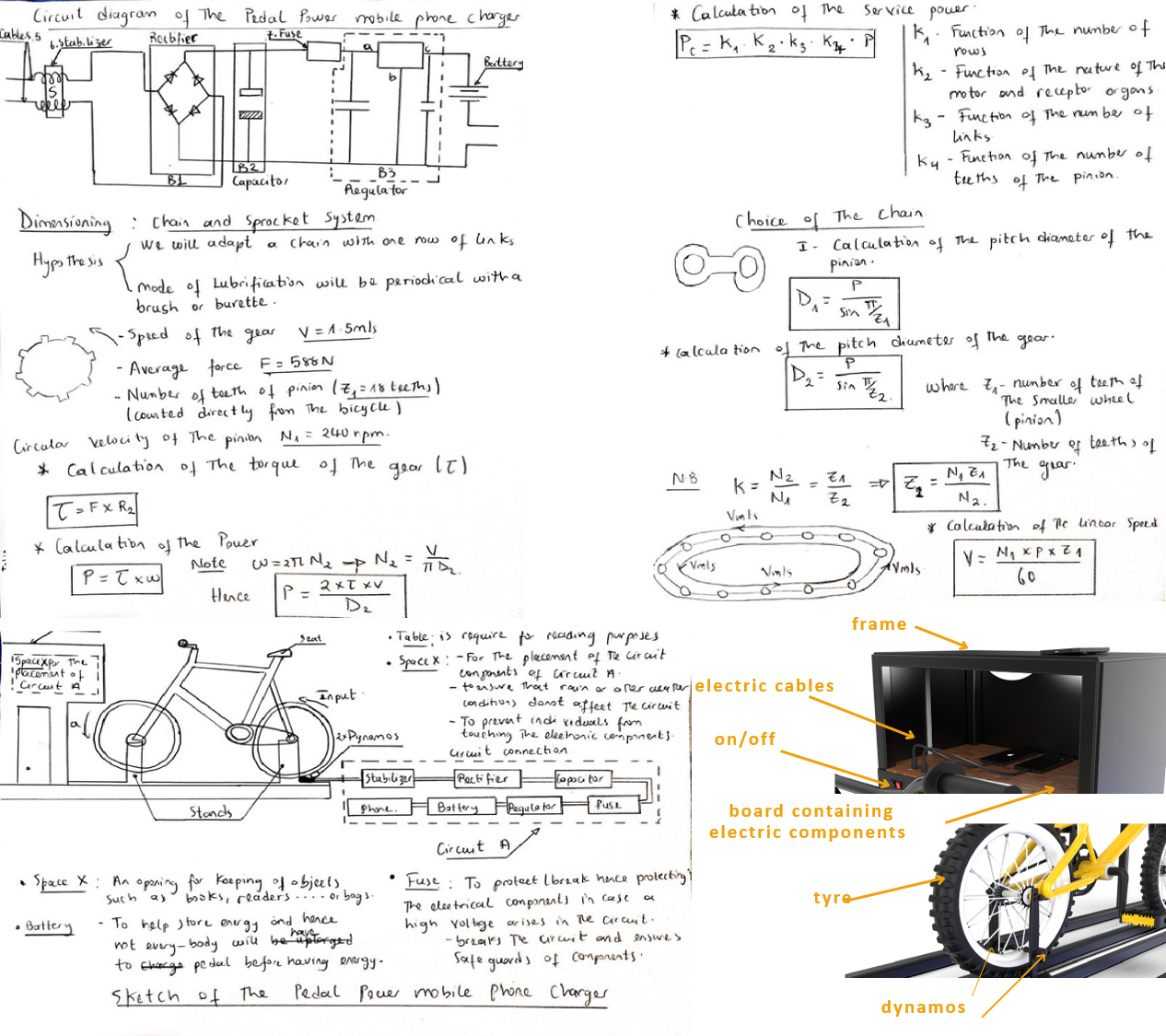

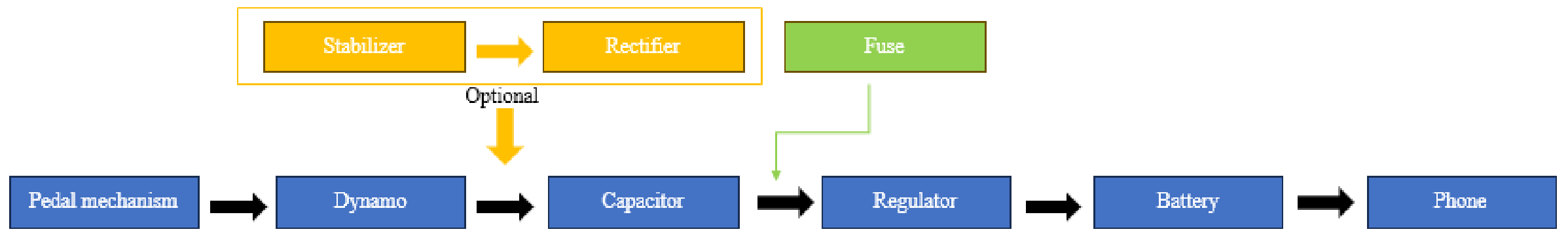

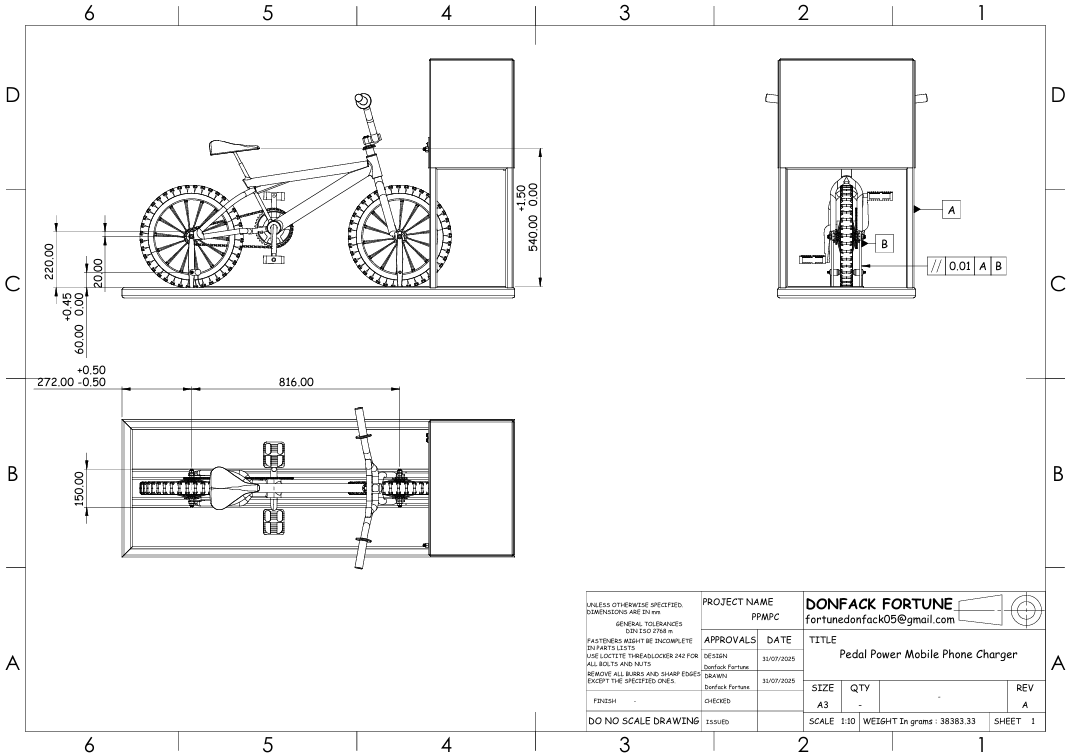

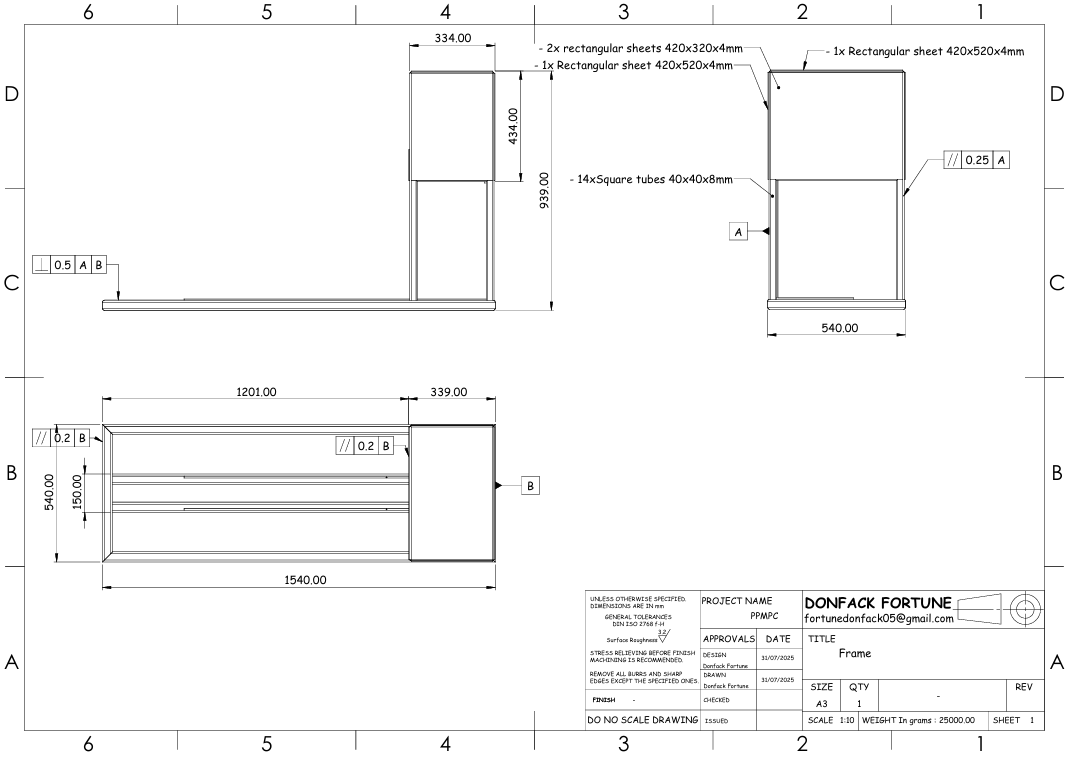

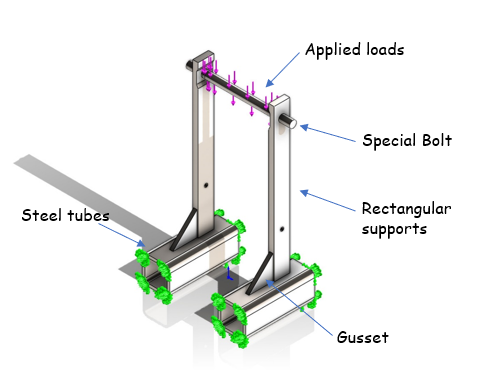

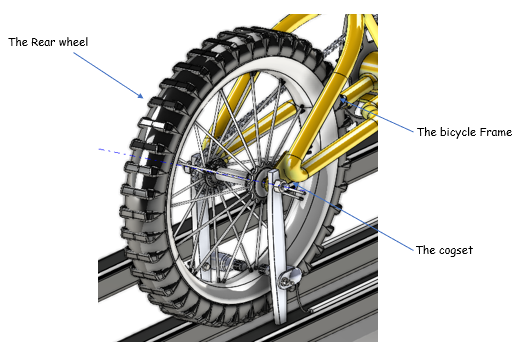

I drove the mechanical design from concept to prototype, teaching myself advanced SolidWorks

weldment techniques and FEA in one week to meet our deadline. The frame design consumed most

of my attention—I iterated through countless sketches to optimize seat height, handlebar

position, and pedal geometry for diverse users while integrating the power transmission

system and electronic components within the structure.

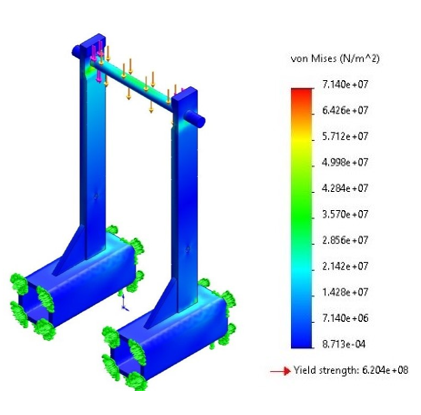

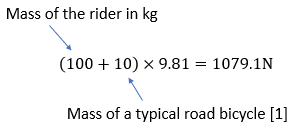

When FEA revealed stress concentrations at critical joints under 800+ N loading, I added

strategic gusset reinforcements to prevent fatigue failure. I balanced competing demands by

selecting hollow steel tubing for its strength-to-weight ratio, achieving our 40 kg

portability target without compromising safety. Beyond technical work, I coordinated task

distribution among teammates and facilitated design reviews where we collectively refined

the CAD models and electronic layouts based on prototyping feedback.

Conclusion

We successfully presented a working prototype at the HTTTC Festival, validating human-powered

charging as viable for energy-scarce environments. This experience taught me that aggressive

deadlines demand ruthless prioritization—mastering SolidWorks in one week meant focusing

only on high-impact skills like weldment design and FEA while deferring less critical

features.

Leading an interdisciplinary team showed me that technical excellence alone isn't enough;

clear communication and collaborative problem-solving proved equally critical. The

simulation-driven design approach not only prevented structural failures but built

confidence in our decisions, reducing costly physical iterations. Most importantly,

optimizing for anthropometric diversity reinforced my commitment to accessible,

user-centered engineering—a principle that now guides all my design work toward solutions

that are both technically sound and socially impactful.